Categories

Sub Categories

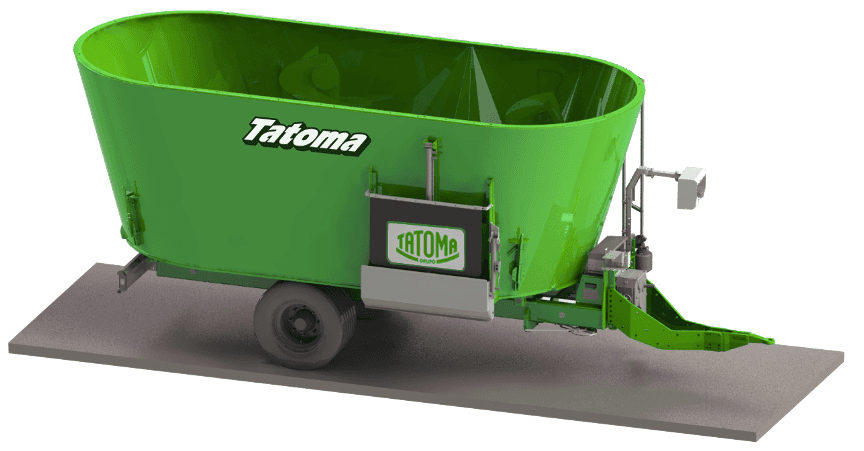

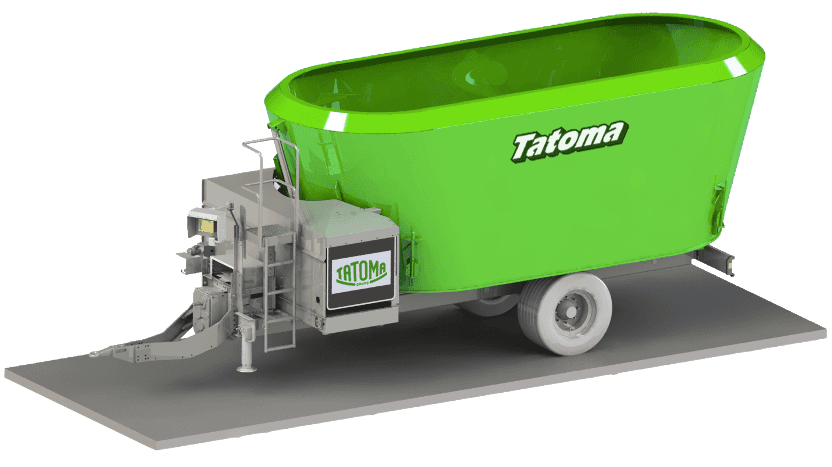

Mod. MTHorizontal mixer / Side discharge door / Available capacities: 247, 353, 459, 565, 706 and 882 cu.ft.

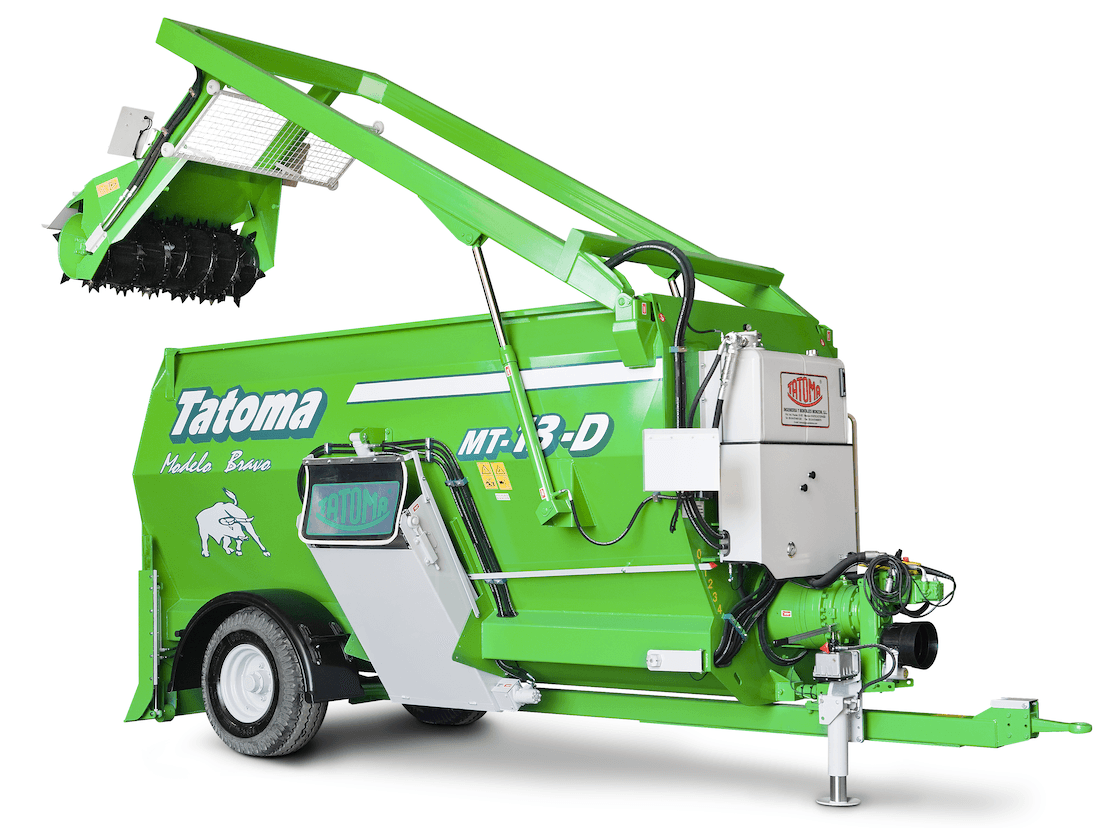

Mod. MTHorizontal mixer / Side discharge door / Available capacities: 247, 353, 459, 565, 706 and 882 cu.ft. Mod. MT-DHorizontal mixer / With silo cutter / Side discharge door / Available capacities: 247, 353, 459, and 565 cu.ft.

Mod. MT-DHorizontal mixer / With silo cutter / Side discharge door / Available capacities: 247, 353, 459, and 565 cu.ft. Mod. VNVertical mixer / One auger / Side discharge door / Available capacities: 141, 212, 283, 353, 424 and 494 cu.ft.

Mod. VNVertical mixer / One auger / Side discharge door / Available capacities: 141, 212, 283, 353, 424 and 494 cu.ft. Mod. VVertical mixer / One auger / Front discharge conveyor / Available capacities: 424 and 494 cu.ft.

Mod. VVertical mixer / One auger / Front discharge conveyor / Available capacities: 424 and 494 cu.ft. Mod. VD DLVertical mixer / Two augers / Side discharge door / Available capacities: 600 and 742 cu.ft.

Mod. VD DLVertical mixer / Two augers / Side discharge door / Available capacities: 600 and 742 cu.ft. Mod. VD DCVertical mixer / Two augers / Front discharge conveyor / Available capacities: 636 and 706 cu.ft.

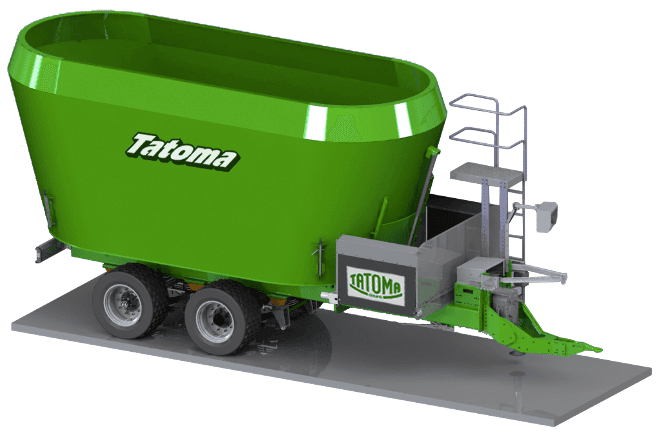

Mod. VD DCVertical mixer / Two augers / Front discharge conveyor / Available capacities: 636 and 706 cu.ft. Mod. MVL-DDVertical mixer / Two augers / Two axles / Side discharge door / Available capacities: 848, 918 and 1059 cu.ft.

Mod. MVL-DDVertical mixer / Two augers / Two axles / Side discharge door / Available capacities: 848, 918 and 1059 cu.ft. Mod. MV-DDVertical mixer / Two augers / Two axles / Front discharge conveyor / Available capacities: 848, 918 and 1059 cu.ft.

Mod. MV-DDVertical mixer / Two augers / Two axles / Front discharge conveyor / Available capacities: 848, 918 and 1059 cu.ft. Mod. MVL-TVertical mixer / Three augers / Two or three axles / 2 Side discharge doors / Available capacities: 1059, 1236, 1413. and 1589 cu.ft.

Mod. MVL-TVertical mixer / Three augers / Two or three axles / 2 Side discharge doors / Available capacities: 1059, 1236, 1413. and 1589 cu.ft. Mod. MV-TVertical mixer / Three augers / Two or three axles / 1 side discharge door + Front discharge conveyor / Available capacities: 1059, 1236, 1413 and 1589 cu.ft.

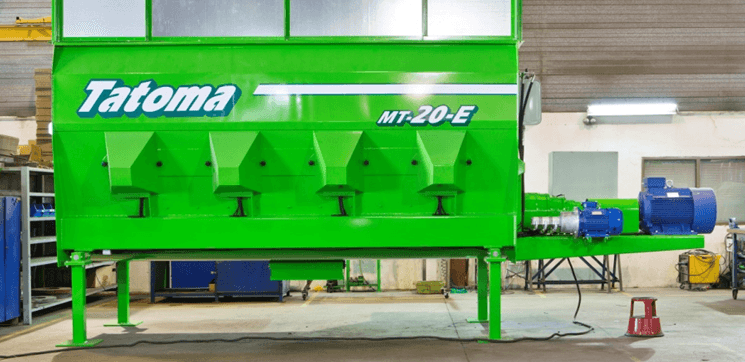

Mod. MV-TVertical mixer / Three augers / Two or three axles / 1 side discharge door + Front discharge conveyor / Available capacities: 1059, 1236, 1413 and 1589 cu.ft. Mod. MT-EHorizontal single auger mixer with round blades: - Tub and auger made of ST52 steel - 3 or 4 weigh cells Ø2 1/8" / 54mm. - The MT25E model comes with 4x Ø2 1/2" /63mm weigh cells. - Programmable scale (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Cardan transmission - Hydraulic belt and gate drive - Hydraulic unit 15CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity.

Mod. MT-EHorizontal single auger mixer with round blades: - Tub and auger made of ST52 steel - 3 or 4 weigh cells Ø2 1/8" / 54mm. - The MT25E model comes with 4x Ø2 1/2" /63mm weigh cells. - Programmable scale (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Cardan transmission - Hydraulic belt and gate drive - Hydraulic unit 15CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity. Mod. MV-ESingle auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity.

Mod. MV-ESingle auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity. Mod. MVD-EDouble auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity.

Mod. MVD-EDouble auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity. Mod. MVT-ETriple auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity.

Mod. MVT-ETriple auger stationary vertical mixer: - The tub and the auger are built in ST52 steel - 4 weighing cells of Ø2 1/8" / Ø 54mm. - Programmable scales (20 servings, 20 ingredients) - Mixer motor 400 / 690V 50Hz (NOT INCLUDED see power) - Transmission with reduction by pulleys and belts - Hydraulic belt and gate drive - Hydraulic unit 7.5 CV 220 / 380V 50Hz with distributors (OPTIONAL) - Electrical cabinet (with electronic starter or frequency inverter) ADDITIONAL INFORMATION The stationary mixers, in order to protect the electric motor, are suggested to be mounted with one of the following systems: - Electronic starter: This system allows a soft start, regulating the voltage and therefore the motor torque, incorporating motor protection. It's the ideal solution for low load or no load starts. - Variable flow control: This system controls the speed of the motor, keeping the motor torque constant, incorporating motor protection. It's the ideal solution when starting with heavy loads or with a full load in the tub. It allows the motor speed to be varied below or above the nominal speed, it controls the current absorbed by the network with great precision, adapts the mixer speed to the working conditions and optimizes electricity consumption, generating significant savings, especially if the motor is not working at 100% of its capacity. MBS-30- CAPACITY: 1059 cu.ft. / 30 m3 and 1130 cu.ft / 32 m3 - MIXER SYSTEM: Mixing system with a dual heavy duty auger and interchangeable resistant knifes Operated by two variable flow pumps and two displacement piston motors coupled to the rear gear. Adjustable mixing speed - FRONT CUTTER AND LOADER: Two 180 hp, adjustable speed motors. Width 87" / 2200 mm. Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. - LOADING BELT: Made of rubber. Adjustable Speed - UNLOADING: Two side doors with stationary PVC belt. Width 39" / 990 mm - WEIGHT SYSTEM: Programmable, 99 recipes x 20 ingredients x 10 discharges, modem output - ENGINE: TIER 4 320 HP VOLVO - FUEL TANK: 66 US gallons / 250 L - TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain - AXLES: Three, the first driving and steerable, second driving and the third steerable. Six wheels 445/65R22.5 - SUSPENSION: Front Hydraulic. Road and off-road modes. Automatic levelling. Rear spring leaf and rocker tandem - STEERING: Servo-assisted hydraulics on the first axle and forced on the third axle. Maximum turning angle of 40 °. - BRAKES: Service, parking and emergency first and second axle - HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin. - CABIN: One-seat. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door and safety glass - CONTROL SYSTEM: PLC electronics. Multifunction joystick to control the forward movement, loading and unloading. Digital display for viewing all machine parameters (hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) - EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform - SPEED: 19 mph / 30 Km/h

MBS-30- CAPACITY: 1059 cu.ft. / 30 m3 and 1130 cu.ft / 32 m3 - MIXER SYSTEM: Mixing system with a dual heavy duty auger and interchangeable resistant knifes Operated by two variable flow pumps and two displacement piston motors coupled to the rear gear. Adjustable mixing speed - FRONT CUTTER AND LOADER: Two 180 hp, adjustable speed motors. Width 87" / 2200 mm. Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. - LOADING BELT: Made of rubber. Adjustable Speed - UNLOADING: Two side doors with stationary PVC belt. Width 39" / 990 mm - WEIGHT SYSTEM: Programmable, 99 recipes x 20 ingredients x 10 discharges, modem output - ENGINE: TIER 4 320 HP VOLVO - FUEL TANK: 66 US gallons / 250 L - TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain - AXLES: Three, the first driving and steerable, second driving and the third steerable. Six wheels 445/65R22.5 - SUSPENSION: Front Hydraulic. Road and off-road modes. Automatic levelling. Rear spring leaf and rocker tandem - STEERING: Servo-assisted hydraulics on the first axle and forced on the third axle. Maximum turning angle of 40 °. - BRAKES: Service, parking and emergency first and second axle - HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin. - CABIN: One-seat. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door and safety glass - CONTROL SYSTEM: PLC electronics. Multifunction joystick to control the forward movement, loading and unloading. Digital display for viewing all machine parameters (hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) - EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform - SPEED: 19 mph / 30 Km/h LINCE MTSCAPACITIES AVAILABLE: - 565 cu.ft. / 16 m3 - 706 cu.ft. / 20 m3 MIXER SYSTEM: Mixing system with a single heavy duty auger and interchangeable resistant knifes. Operated by a variable flow pump and piston engine coupled to the planetary at the rear. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. 79" width (2000 mm). Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING: 37" / 930mm long side belt with hydraulic lift WEIGHT SYSTEM: Programmable scales, 99 recipes x 20 ingredients x 10 discharges, modem output. ENGINES - LINCE MTS-16-H V25: TIER 4B 170 HP / IVECO - LINCE MTS-20-H V25: TIER 4B 205 HP / IVECO FUEL TANK: 42 or 46 US galloons, depending on the model. TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain AXLES: One steerable at front. Front wheels 305/70R19.5, rear wheels 445/65R22.5 SUSPENSION: Front springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located on the side cabinet on the tub CABIN: One-seat. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reducer oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform SPEED: 16 mph / 25 Km/h

LINCE MTSCAPACITIES AVAILABLE: - 565 cu.ft. / 16 m3 - 706 cu.ft. / 20 m3 MIXER SYSTEM: Mixing system with a single heavy duty auger and interchangeable resistant knifes. Operated by a variable flow pump and piston engine coupled to the planetary at the rear. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. 79" width (2000 mm). Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING: 37" / 930mm long side belt with hydraulic lift WEIGHT SYSTEM: Programmable scales, 99 recipes x 20 ingredients x 10 discharges, modem output. ENGINES - LINCE MTS-16-H V25: TIER 4B 170 HP / IVECO - LINCE MTS-20-H V25: TIER 4B 205 HP / IVECO FUEL TANK: 42 or 46 US galloons, depending on the model. TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain AXLES: One steerable at front. Front wheels 305/70R19.5, rear wheels 445/65R22.5 SUSPENSION: Front springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located on the side cabinet on the tub CABIN: One-seat. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reducer oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform SPEED: 16 mph / 25 Km/h MASTER MMSCAPACITIES AVAILABLE: - 353, 459 and 565 cu.ft. - 10, 13 and 16 m3 MIXER SYSTEM: Mixing system with a single heavy duty auger and interchangeable resistant knifes. Operated by a variable flow pump and piston engine coupled to the planetary at the rear. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars UNLOADING SYSTEM: 37" / 930 mm long side conveyor with hydraulic elevation. WEIGHT SYSTEM: Programmable scales, 20 recipes x 20 ingredients ENGINE - TIER 3 175 HP / IVECO - TIER 4A 170 HP / IVECO and 205 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED 16 mph. / 25 Km/h

MASTER MMSCAPACITIES AVAILABLE: - 353, 459 and 565 cu.ft. - 10, 13 and 16 m3 MIXER SYSTEM: Mixing system with a single heavy duty auger and interchangeable resistant knifes. Operated by a variable flow pump and piston engine coupled to the planetary at the rear. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Electrically driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars UNLOADING SYSTEM: 37" / 930 mm long side conveyor with hydraulic elevation. WEIGHT SYSTEM: Programmable scales, 20 recipes x 20 ingredients ENGINE - TIER 3 175 HP / IVECO - TIER 4A 170 HP / IVECO and 205 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED 16 mph. / 25 Km/h BELMIX MVS-DLAVAILABLE CAPACITIES - 353, 424 and 494 cu.ft - 10, 12 and 14 m3 MIXER SYSTEM: Mixing system with a single heavy duty vertical auger and interchangeable resistant knifes. Driven by a variable flow pump and piston engine. Adjustable mixing speed FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 79" / 2000 mm. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING SYSTEM: By tub flat side door with unloading conveyor WEIGHT SYSTEM Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4A: 170 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5, optional 425/40B17 can be mounted on the rear axle (incompatible with options 4-wheel drive or dual steering axis) SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on front axle HYDRAULIC AND ELECTRICAL Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h

BELMIX MVS-DLAVAILABLE CAPACITIES - 353, 424 and 494 cu.ft - 10, 12 and 14 m3 MIXER SYSTEM: Mixing system with a single heavy duty vertical auger and interchangeable resistant knifes. Driven by a variable flow pump and piston engine. Adjustable mixing speed FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 79" / 2000 mm. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING SYSTEM: By tub flat side door with unloading conveyor WEIGHT SYSTEM Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4A: 170 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5, optional 425/40B17 can be mounted on the rear axle (incompatible with options 4-wheel drive or dual steering axis) SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on front axle HYDRAULIC AND ELECTRICAL Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h BELMIX MVS-DCAVAILABLE CAPACITIES - 353, 424 and 494 cu.ft - 10, 12 and 14 m3 MIXER SYSTEM: Mixing system with a single heavy duty vertical auger and interchangeable resistant knifes. Driven by a variable flow pump and piston engine. Adjustable mixing speed FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 79" / 2000 mm. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING SYSTEM: Rear conveyor made in carbon steel WEIGHT SYSTEM Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4A: 170 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5, optional 425/40B17 can be mounted on the rear axle (incompatible with options 4-wheel drive or dual steering axis) SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on front axle HYDRAULIC AND ELECTRICAL Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h

BELMIX MVS-DCAVAILABLE CAPACITIES - 353, 424 and 494 cu.ft - 10, 12 and 14 m3 MIXER SYSTEM: Mixing system with a single heavy duty vertical auger and interchangeable resistant knifes. Driven by a variable flow pump and piston engine. Adjustable mixing speed FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 79" / 2000 mm. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of polyethylene chain and cross bars. UNLOADING SYSTEM: Rear conveyor made in carbon steel WEIGHT SYSTEM Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4A: 170 HP / IVECO FUEL TANK: 42 US Gallon / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5, optional 425/40B17 can be mounted on the rear axle (incompatible with options 4-wheel drive or dual steering axis) SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40 ° BRAKES: Service, parking and emergency on front axle HYDRAULIC AND ELECTRICAL Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h DUPLOMIX MVS-DLAVAILABLE CAPACITIES: - 600 and 671cu.ft. - 17 and 19 m3 MIXER SYSTEM: Mixing system with dual heavy duty vertical auger and interchangeable resistant knives. Driven by a variable flow pump and piston engine. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber. UNLOADING Flat side door with mecanical folding chute WEIGHT SYSTEM: Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4B: 205 HP / IVECO FUEL TANK: 42 US Gal / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on front axle. HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass. CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h

DUPLOMIX MVS-DLAVAILABLE CAPACITIES: - 600 and 671cu.ft. - 17 and 19 m3 MIXER SYSTEM: Mixing system with dual heavy duty vertical auger and interchangeable resistant knives. Driven by a variable flow pump and piston engine. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber. UNLOADING Flat side door with mecanical folding chute WEIGHT SYSTEM: Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4B: 205 HP / IVECO FUEL TANK: 42 US Gal / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on front axle. HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass. CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h DUPLOMIX MVS-DCAVAILABLE CAPACITIES: - 600 and 671cu.ft. - 17 and 19 m3 MIXER SYSTEM: Mixing system with dual heavy duty vertical auger and interchangeable resistant knives. Driven by a variable flow pump and piston engine. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber. UNLOADING Rear conveyor made of carbon steel WEIGHT SYSTEM: Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4B: 205 HP / IVECO FUEL TANK: 42 US Gal / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on front axle. HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass. CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h

DUPLOMIX MVS-DCAVAILABLE CAPACITIES: - 600 and 671cu.ft. - 17 and 19 m3 MIXER SYSTEM: Mixing system with dual heavy duty vertical auger and interchangeable resistant knives. Driven by a variable flow pump and piston engine. Adjustable mixing speed. FRONT CUTTER AND LOADER: 130 hp, adjustable speed motor. Width 2000 mm / 79". Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber. UNLOADING Rear conveyor made of carbon steel WEIGHT SYSTEM: Programmable, 20 recipes x 20 ingredients ENGINE: - TIER 3: 175 HP / IVECO - TIER 4B: 205 HP / IVECO FUEL TANK: 42 US Gal / 160 L TRANSMISSION: Hydrostatic closed circuit. Driven by a variable flow pump and piston motor. AXLES: Two, front drive and steering. Four wheels 445/45R19.5 SUSPENSION: Front and rear leaf springs STEERING: Hydraulic servo. Maximum turning angle of 40° BRAKES: Service, parking and emergency on front axle. HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass. CONTROL SYSTEM: Multifunction joystick, buttons and indicators (reductor oil temperature, hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) EQUIPMENT Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD SPEED: 16 mph / 25 Km/h GIGAMIX MVS-HVAVAILABLE CAPACITIES - 635, 706, 777, 918 and 1197 cu.ft. - 18, 20, 22, 26 and 34 m3 MIXER SYSTEM: Mixing system with two heavy duty vertical augers and interchangeable resistant knifes. Driven by two pumps and two variable displacement radial piston engines. Adjustable mixing speed and fast speed for weigh scale control discharge to ensure the tub is properly emptied FRONT CUTTER AND LOADER: 130 hp motor with adjustable speed. 87" / 2200 mm cutting width. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber, with adjustable speed. UNLOADING By flat side door with folding chute WEIGHT SYSTEM: Programmable, 99 recipes x 20 ingredients x 10 discharges, modem output ENGINE: - TIER 3: 238 HP / IVECO - TIER 4B: 205 HP / IVECO and 286 HP / IVECO FUEL TANK: 66 US Gallon / 250 L TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain. AXLES: Two, steering and wheel drive. Four wheels 445/65R22.5 SUSPENSION: Front and rear hydraulics. Road and off-road modes. Automatic Levelling STEERING: Hydraulic servo. Maximum turning angle of 40 °. Three modes, road, full turn and crab BRAKES: Service on both axles. Service and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: "PLC electronics. Multifunction joystick to control the forward movement, loading and unloading. Digital display for viewing all machine parameters (hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) Control system by electronic management includes: - Digital and autonomous screen for the control of all functions of the machine; - Electronic system for the control of the displacement, load and unload; - Electronic tuning for the mix velocity. Variable acceleration system for displacement (improves consume and noise reduction); - Velocity regulation of the unload conveyor; - Trigger the silage cutter with electronic pedal that allows the velocity regulation in function of the products to upload". EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform SPEED: 25 mph / 40 Km/h

GIGAMIX MVS-HVAVAILABLE CAPACITIES - 635, 706, 777, 918 and 1197 cu.ft. - 18, 20, 22, 26 and 34 m3 MIXER SYSTEM: Mixing system with two heavy duty vertical augers and interchangeable resistant knifes. Driven by two pumps and two variable displacement radial piston engines. Adjustable mixing speed and fast speed for weigh scale control discharge to ensure the tub is properly emptied FRONT CUTTER AND LOADER: 130 hp motor with adjustable speed. 87" / 2200 mm cutting width. Manually driven lowering adjustment in the control panel, lowering cut-out by pressure switch depending on the working pressure of the cutter. Driven by a variable flow pump and orbital motors. LOADING BELT: Made of rubber, with adjustable speed. UNLOADING By flat side door with folding chute WEIGHT SYSTEM: Programmable, 99 recipes x 20 ingredients x 10 discharges, modem output ENGINE: - TIER 3: 238 HP / IVECO - TIER 4B: 205 HP / IVECO and 286 HP / IVECO FUEL TANK: 66 US Gallon / 250 L TRANSMISSION: Hydrostatic closed circuit. Variable flow pump and two piston engines, including flow divider to ensure traction on the first and second axle when driving through difficult terrain. AXLES: Two, steering and wheel drive. Four wheels 445/65R22.5 SUSPENSION: Front and rear hydraulics. Road and off-road modes. Automatic Levelling STEERING: Hydraulic servo. Maximum turning angle of 40 °. Three modes, road, full turn and crab BRAKES: Service on both axles. Service and emergency on rear axle HYDRAULIC AND ELECTRICAL: Circuits designed to work in harsh environmental conditions. Compliant with European machines safety and electromagnetic incompatibility regulations. Located behind the cabin CABIN: One-seater. Manufactured in steel with anti-corrosion chemical treatment. Optimal visibility of the environment (inward sloping windshield). Swing door. Safety glass CONTROL SYSTEM: "PLC electronics. Multifunction joystick to control the forward movement, loading and unloading. Digital display for viewing all machine parameters (hydraulic oil temperature, mixer pressure, cutter pressure, hydraulic oil level, breakdown lights ...) Control system by electronic management includes: - Digital and autonomous screen for the control of all functions of the machine; - Electronic system for the control of the displacement, load and unload; - Electronic tuning for the mix velocity. Variable acceleration system for displacement (improves consume and noise reduction); - Velocity regulation of the unload conveyor; - Trigger the silage cutter with electronic pedal that allows the velocity regulation in function of the products to upload". EQUIPMENT: Two spotlights front and two rear, air suspension seat, fire extinguisher, water heating, radio CD, tool box, step ladder with platform SPEED: 25 mph / 40 Km/h EM350 / EM650The standard model includes: - Trailered straw chopper - Heavy duty turbine plate Ø1600 mm / Ø63" with 8 reinforced and bolted paddles, easy to replace - High resistance bottom chain Ø12 mm / 0.5" with crossbars, easy to replace - Bottom moving floor driven by an hydraulic motor - Double bottom plate with stone collector - Folding rear door with 2 hydraulic cylinders - Controlled with hydraulic distributor and flex controls - 2 speed gearbox - Unloading through side chute

EM350 / EM650The standard model includes: - Trailered straw chopper - Heavy duty turbine plate Ø1600 mm / Ø63" with 8 reinforced and bolted paddles, easy to replace - High resistance bottom chain Ø12 mm / 0.5" with crossbars, easy to replace - Bottom moving floor driven by an hydraulic motor - Double bottom plate with stone collector - Folding rear door with 2 hydraulic cylinders - Controlled with hydraulic distributor and flex controls - 2 speed gearbox - Unloading through side chute EM1500 / EM2000The standard model includes: - Trailered straw chopper - Heavy duty turbine plate Ø1800 mm/Ø71" with 8 reinforced bolted paddles, easy to replace - High resistance flat chain (100 mm / 4") x 12 crossbars, easy to disassemble - Bottom mobile floor driven by an hydraulic motor with pressure gauge - Double bottom plate with stone collector - Rear door opens horizontally with hinges - Hydraulic front jack - Controlled with hydraulic distributor and flex controls - 2 speed gearbox with manual control - Hydraulic and manual brakes - Unloading through side chute

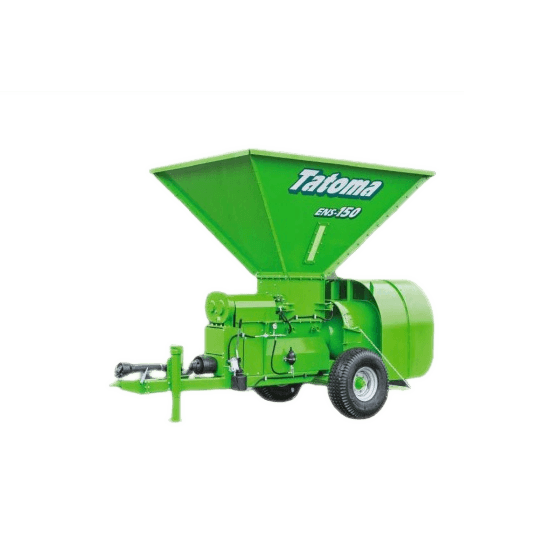

EM1500 / EM2000The standard model includes: - Trailered straw chopper - Heavy duty turbine plate Ø1800 mm/Ø71" with 8 reinforced bolted paddles, easy to replace - High resistance flat chain (100 mm / 4") x 12 crossbars, easy to disassemble - Bottom mobile floor driven by an hydraulic motor with pressure gauge - Double bottom plate with stone collector - Rear door opens horizontally with hinges - Hydraulic front jack - Controlled with hydraulic distributor and flex controls - 2 speed gearbox with manual control - Hydraulic and manual brakes - Unloading through side chute Mod. ENSThe standard model includes: - Silage bagger and grain crusher - Yield: 20 a 25 Tn/h - Hopper capacity: 3,5 m3 - Total wheight: 2.300 kg Bag diameter: - ENS 150: 5 feet - ENS 200: 6,5 feet - Bagging through auger - Two teethed crushing rollers - Hydraulic brake - Hydraulic adjustement for the crushing rollers - Pto shaft driven - Chain driven auger

Mod. ENSThe standard model includes: - Silage bagger and grain crusher - Yield: 20 a 25 Tn/h - Hopper capacity: 3,5 m3 - Total wheight: 2.300 kg Bag diameter: - ENS 150: 5 feet - ENS 200: 6,5 feet - Bagging through auger - Two teethed crushing rollers - Hydraulic brake - Hydraulic adjustement for the crushing rollers - Pto shaft driven - Chain driven auger Mod. T- PVC belt 2 Sizes: - T-100: 35.2 cu.ft. - T-150: 53.0 cu.ft.

Mod. T- PVC belt 2 Sizes: - T-100: 35.2 cu.ft. - T-150: 53.0 cu.ft. Feed PlantsDESIGN Tailored to EACH customer’s needs. The project will depend on the number and type of ingredients to be mixed, the volume of the hourly or daily amount of product to be mixed, and how the mixed product must be delivered (immediate delivery, later sale, or storage). WHY CONSIDERING A FEED PLANT? One of the most important objectives, from the point of view of ruminant livestock feeding, is to ensure that the cattle receive the same amount of nutrients at each feed, and with the same characteristics as those planned by the nutritionist. Only through our automated mixing method is it possible to achieve that the programmed ration is the one consumed by the animal with almost 100% accuracy, achieving an optimization in the intake so that the cattle receive the same ration every day, totally homogeneous and with the same color and fiber sizes. This fact affects less fluctuation in milk production, avoiding ups and downs, so that if the ration is always the same, production will only vary according to lactation periods or distances to delivery. The system also allows adapting the ration, by precisely adjusting the ingredients, to the animal's production cycle. ADVANTAGES IN FRONT TO OTHER MIXING MEANS (PULL-TYPE OR SELFPROPELED MIXERS) • It will be possible to produce an homogeneous and identical ration to the one programmed by the nutritionist • It will be possible to reduce the shrink and waste of ingredients thanks to the automation of the system, with the consequent saving of money. • Significant reduction in energy consumption. • Milk production and regularity in the gestation of animals are substantially improved. • The amortization of the machinery can be done in 4 years maximum, due to the improvement of the system. • The number of workers is reduced substantially. There is less dependence on qualified personnel.

Feed PlantsDESIGN Tailored to EACH customer’s needs. The project will depend on the number and type of ingredients to be mixed, the volume of the hourly or daily amount of product to be mixed, and how the mixed product must be delivered (immediate delivery, later sale, or storage). WHY CONSIDERING A FEED PLANT? One of the most important objectives, from the point of view of ruminant livestock feeding, is to ensure that the cattle receive the same amount of nutrients at each feed, and with the same characteristics as those planned by the nutritionist. Only through our automated mixing method is it possible to achieve that the programmed ration is the one consumed by the animal with almost 100% accuracy, achieving an optimization in the intake so that the cattle receive the same ration every day, totally homogeneous and with the same color and fiber sizes. This fact affects less fluctuation in milk production, avoiding ups and downs, so that if the ration is always the same, production will only vary according to lactation periods or distances to delivery. The system also allows adapting the ration, by precisely adjusting the ingredients, to the animal's production cycle. ADVANTAGES IN FRONT TO OTHER MIXING MEANS (PULL-TYPE OR SELFPROPELED MIXERS) • It will be possible to produce an homogeneous and identical ration to the one programmed by the nutritionist • It will be possible to reduce the shrink and waste of ingredients thanks to the automation of the system, with the consequent saving of money. • Significant reduction in energy consumption. • Milk production and regularity in the gestation of animals are substantially improved. • The amortization of the machinery can be done in 4 years maximum, due to the improvement of the system. • The number of workers is reduced substantially. There is less dependence on qualified personnel.- Straw processing plantsPlease contact for further information.

Perin 150It can be used on: - Pull-type mixers - Self propelled mixers - Stationary mixers Main operating and technical features. - Economic weight indicator for partial and total weighing. - Very easy to install and to use. - Weight display: 4 digits, red LED on black screen (digits 25 mm high). - Very good visibility even in poor light conditions. - Function keys en the frontal panel. - Key to block the weight value. - Weight display in Kg or in pounds. - Switching, calibration, tare and battery test by means of keys. - MIL type connectors for power supply and load cells. - Compact ABS box. - Power supply 12 Volts 0,3 Amp. - Working temperature: - 10ºC / +40ºC. - Kgs and Lbs

Perin 150It can be used on: - Pull-type mixers - Self propelled mixers - Stationary mixers Main operating and technical features. - Economic weight indicator for partial and total weighing. - Very easy to install and to use. - Weight display: 4 digits, red LED on black screen (digits 25 mm high). - Very good visibility even in poor light conditions. - Function keys en the frontal panel. - Key to block the weight value. - Weight display in Kg or in pounds. - Switching, calibration, tare and battery test by means of keys. - MIL type connectors for power supply and load cells. - Compact ABS box. - Power supply 12 Volts 0,3 Amp. - Working temperature: - 10ºC / +40ºC. - Kgs and Lbs Perin 800- Big display, good visibility in any light condition. - Big keys and easy use. - New SET/ RECALL function to recall frequent weighings. Main characteristics: - Backlit LCD display with announcements and messages related with the current operation . - Digits 57mm high that allows a very good visibiliy from a distance. - Programmable scale (20 recipes x 20 ingredients) - Can be programmable each in total values or per animal - Switch to connect a buzzer - Possibility to connect remote display to the StarBus protocol output. - A remote display by cable or via radio can be connected: LCD REM/40A numeric black digits h 40 mm LED REM/40B numeric red digits h 40 mm LED REM 57 numeric red digits h 57 mm

Perin 800- Big display, good visibility in any light condition. - Big keys and easy use. - New SET/ RECALL function to recall frequent weighings. Main characteristics: - Backlit LCD display with announcements and messages related with the current operation . - Digits 57mm high that allows a very good visibiliy from a distance. - Programmable scale (20 recipes x 20 ingredients) - Can be programmable each in total values or per animal - Switch to connect a buzzer - Possibility to connect remote display to the StarBus protocol output. - A remote display by cable or via radio can be connected: LCD REM/40A numeric black digits h 40 mm LED REM/40B numeric red digits h 40 mm LED REM 57 numeric red digits h 57 mm Perin 1500/1510It can be used on the following systems: - Pull type mixer - Self Propelled mixer - Stationary mixer Main characteristics - Numerical backlit LCD (mod.1500-1520) or display with red LED digits (1510-1530) for weight and for recipe/ ingredient number. - Additional alphanumerical backlit LCD for help messages and names of recipes, ingredientes and unloading groups. - Display announcers indicating the present operation. - Function key for a quick recall of operation - Function keys for a quick recall of operation - Alphanumerical keyboard for an easy entry of vales and names. - Wide memory for 20 recipes, further expandible with memory cartridge. - Name list for recipes, components and unloading groups. - Menu and messages available in different languages - Possibility to print the total duration of loading/ unloading operations. - Possibility to reprint the last operation automatically or on demand. - Possibility connect several peripherals to the serial protocol StarBus output. - Possibility to connect memory cartridge to use the software for traceability management FarmLink.

Perin 1500/1510It can be used on the following systems: - Pull type mixer - Self Propelled mixer - Stationary mixer Main characteristics - Numerical backlit LCD (mod.1500-1520) or display with red LED digits (1510-1530) for weight and for recipe/ ingredient number. - Additional alphanumerical backlit LCD for help messages and names of recipes, ingredientes and unloading groups. - Display announcers indicating the present operation. - Function key for a quick recall of operation - Function keys for a quick recall of operation - Alphanumerical keyboard for an easy entry of vales and names. - Wide memory for 20 recipes, further expandible with memory cartridge. - Name list for recipes, components and unloading groups. - Menu and messages available in different languages - Possibility to print the total duration of loading/ unloading operations. - Possibility to reprint the last operation automatically or on demand. - Possibility connect several peripherals to the serial protocol StarBus output. - Possibility to connect memory cartridge to use the software for traceability management FarmLink. Hydroshift systemThe advantages of the system are the following: - It controls the mixing process in a continuous and automatically; - The speed of the augers is adjusted depending on the ingredients loaded; - It improves the homogeneity of the mix, without using expertise labor; - The bale retainers work automatically; - Fast and complete unloading, using the unloading mode; - The system adapts to the tractor’s horsepower; - The speed of the augers allows to cut the fiber rapidly; - Allows to work low volume loads; - It optimizes the time of use of the mixer; - It is posible to program any rotational speed of the augers, from 0 to 55 rpm: - It allows to start the tractor progressively, with the mixer is full loaded; - It is posible to program a máximum power, in order to use the mixer with any tractor.

Hydroshift systemThe advantages of the system are the following: - It controls the mixing process in a continuous and automatically; - The speed of the augers is adjusted depending on the ingredients loaded; - It improves the homogeneity of the mix, without using expertise labor; - The bale retainers work automatically; - Fast and complete unloading, using the unloading mode; - The system adapts to the tractor’s horsepower; - The speed of the augers allows to cut the fiber rapidly; - Allows to work low volume loads; - It optimizes the time of use of the mixer; - It is posible to program any rotational speed of the augers, from 0 to 55 rpm: - It allows to start the tractor progressively, with the mixer is full loaded; - It is posible to program a máximum power, in order to use the mixer with any tractor. FIDMIXThis application is adapted by the user according to his needs. Contact for more information.

FIDMIXThis application is adapted by the user according to his needs. Contact for more information. Mod MVL-DVertical mixer / Two augers / One axle / Side discharge door / Available capacities: 512, 565, 636, 706, and 777 cu.ft.

Mod MVL-DVertical mixer / Two augers / One axle / Side discharge door / Available capacities: 512, 565, 636, 706, and 777 cu.ft. Mod. MV-DVertical mixer / Two augers / One axle / Front discharge conveyor / Available capacities: 512, 565, 636, 706, and 777 cu.ft.

Mod. MV-DVertical mixer / Two augers / One axle / Front discharge conveyor / Available capacities: 512, 565, 636, 706, and 777 cu.ft.